Lean Academy - UK - How to learn from Toyota

UK -Auto Industry -15th June 2006: -- In a presentation to the National Health Service Confederation yesterday, Professor Dan Jones, formerly of Cardiff Business School and the founder and chairman of the Lean Academy and co-author of the best-selling automotive industry text, "The Machine that Changed the World", suggested that the National Health Service could learn much from Toyota’s production system and its kaizen processes... The lessons from Toyota 'applicable to hospitals’ work could be applied on three levels, said Professor Jones:

UK -Auto Industry -15th June 2006: -- In a presentation to the National Health Service Confederation yesterday, Professor Dan Jones, formerly of Cardiff Business School and the founder and chairman of the Lean Academy and co-author of the best-selling automotive industry text, "The Machine that Changed the World", suggested that the National Health Service could learn much from Toyota’s production system and its kaizen processes... The lessons from Toyota 'applicable to hospitals’ work could be applied on three levels, said Professor Jones:-- Transforming the way each activity is performed, and the work of departments like pathology, radiology, etc. – ‘Point kaizen’

-- Redesigning patient ‘journeys’ from end to end – ‘Value stream kaizen’

-- Rethinking the way organisations manage these journeys and synchronise the necessary support activities – ‘System kaizen’...

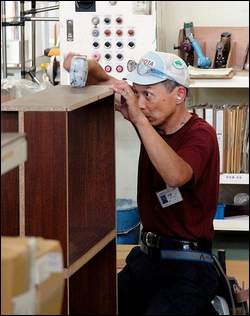

* Toyota factory pumps out homes

KASUGAI, Japan -Associated Press, by Yuri Kageyama/The Detroit News -June 15, 2006: -- Automaker banks on famed production methods to build 7,000 houses a year for the Japanese market... Cubicles that are bits of homes, tucked with stairways, built-in closets and pink bathtubs, roll off the assembly line at a bustling Toyota plant in central Japan... Kasugai Housing Works, a plant for prefabricated housing run by Toyota Motor Corp., prides itself on the same production methods that gave the Japanese automaker a worldwide reputation for quality and efficiency... Housing makes up less than 1 percent of Toyota's $183 billion annual sales. But company officials say technology acquired from years of making cars is central to homebuilding Toyota style... (Photo: Katsumi Kasahara / Associated Press -- An assembly line worker adjusts a drawer for a built-in closet to be tucked in one of the cubicles that will become a Toyota pre-made home)

![Validate my Atom 1.0 feed [Valid Atom 1.0]](valid-atom.png)

0 Comments:

Post a Comment

<< Home